Product Description

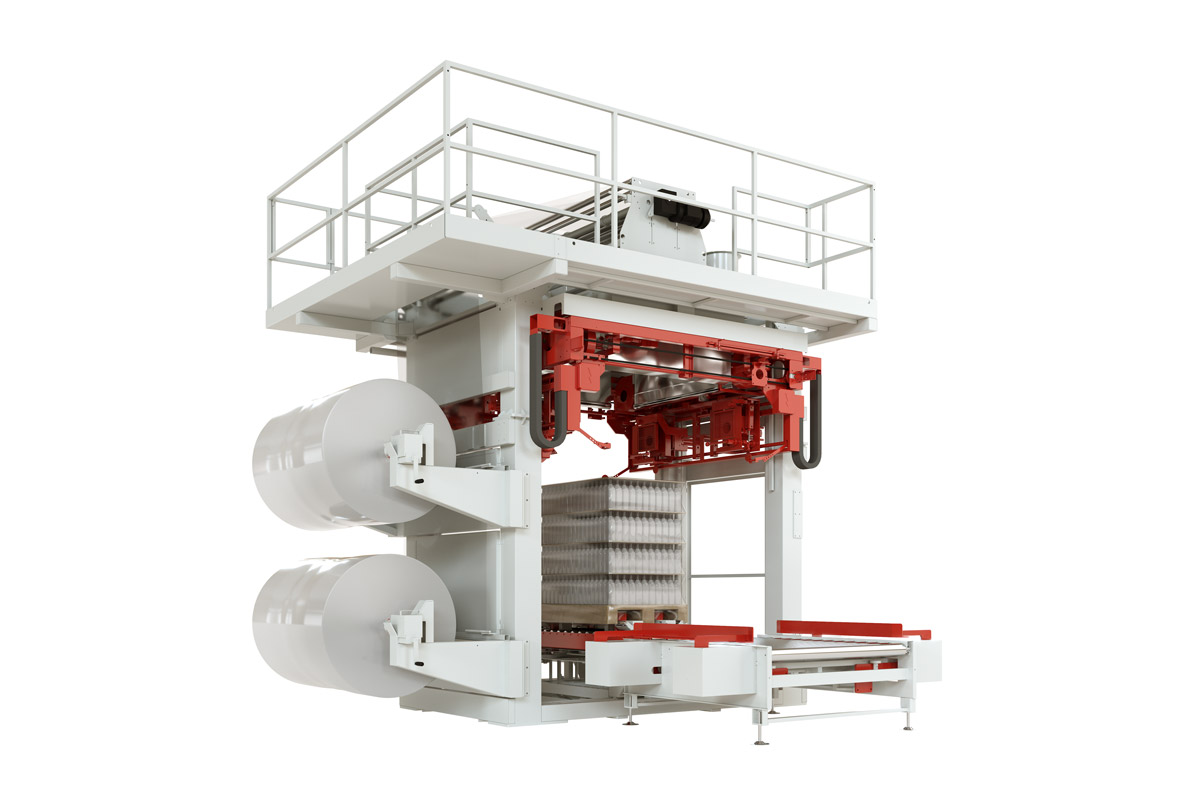

It is a perfect space saving piece of equipment that significantly reduces its footprint, having the combined hooding/shrinking process in one machine only.

The pallet is automatically detected for the film feed to prepare the right film size, the plastic hood is tailored cut and sealed to reduce the amount of plastic used.

Recycled hot air system

The shrinking process is made through a stainless-steel ring which uses a patented system of controlled recycled hot air to evenly and gently heat up the plastic on the 4 sides around the load; no direct contact with flames does in fact preserve the film elasticity and resistance.

Advanced technology

The FTB419 works with any type of low-pressure gas. It is also available in an electrical version.

Bocedi machines are known to be flexible and fast. The FTB419 fits perfectly in the company standards. It can in fact be configurated with up to 6 different film sizes and it can operate more than 100 pallets/hr.

Technical data

| Capacity | 100 pallet/hr |

| Minimum pallet size | 600×800 mm |

| Maximum pallet size | On request |