LASERAX

Laserax works with the world’s leading manufacturers to implement automated laser cleaning, welding, texturing, and marking solutions. Providing turnkey machines and OEM systems, the driving force behind Laserax is the desire to push the limits of laser technology and establish new standards in the industry.

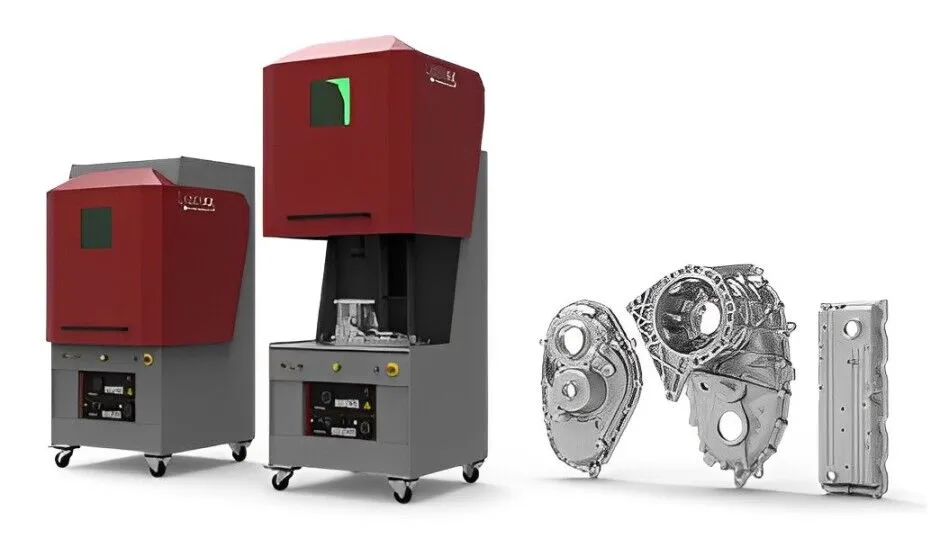

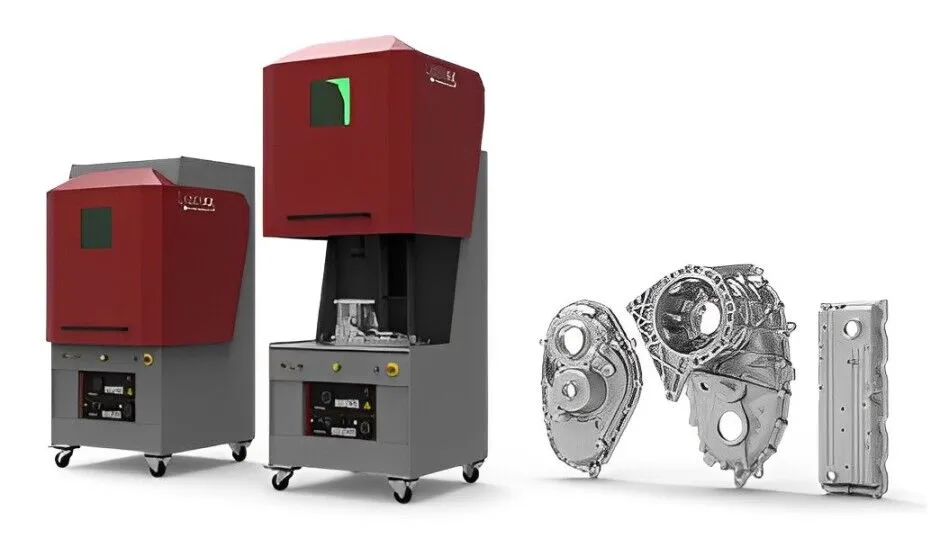

Laser Cleaning Systems

From low-power to highpower lasers, our range of products allow manufacturers to efficiently solve their surface cleaning needs.

Laser Markers - OEM Laser Marking Systems

Each laser series offers a different range of power, operates at a specific wavelength and is optimized for different applications. Our fiber laser marking systems are optimized to process metals, whereas our CO2 laser marking systems are optimized for organic materials.

Laser Marking & Engraving Machines

- Flex Laser Marking Workstation

Rotary Laser Workstation

Laser Welding Machines

- Laser Welding Workstation

Laser Welding Machine

Manual & Automated Laser Cleaning Machines

- Manual Laser Cleaning Workstation

- Rotary Laser Cleaning Workstation

Battery Laser Cleaning Workstation